In recent days, digital printing has become a top topic in textile printing industry. As we all known that from the the word ‘digital’, we can know that the textile printing has become more intelligent and more efficient than ever. So now, Subtextile will present you 4 tips to help you optimize your digital printing process.

1.Regular maintenance of your print nozzle

The print nozzle is the most valuable and most delicate part of the sublimation printer. Even the smallest one will cost a lot and it only has very limited life span. Therefore, in the printing process, attention should be paid to the protection of the nozzles. Some machine manufacturers have trolley anti-collision devices on the machines. Usually, the nozzles should be regularly maintained and repaired. To replace the ink, the ink should be cleaned with a cleaning solution. After printing, wipe the nozzle with a clean cloth and a cleaning solution to prevent the ink from solidifying and blocking the nozzle of the industry sublimation printer.

2.Upgrade the pressure roller, buy a digital printer with a large rubber roller

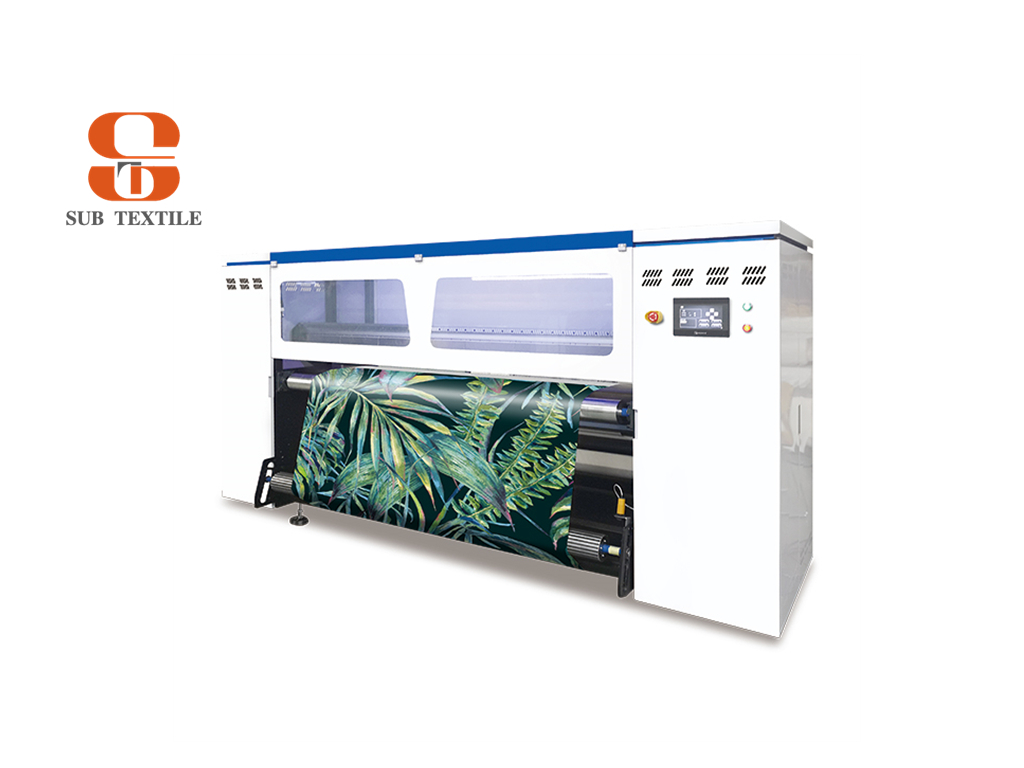

Nowadays some of the products on the market use anti-static voltage paper wheels to feed paper. The effect is good, but it is inevitable that there will be jams and arch papers. Subtextile offers the 8-head heat transfer paper printer of upgraded model uses a large rubber roller to feed sublimation ink paper, which has better adsorption performance, it can meet the printing requirements for ‘super-concentration ink + 8 nozzles + 30g thin sublimation paper’.

3.The sublimation ink system should be equipped with constant temperature system to reduce the printing color difference

We all know that the digital sublimation printing machine is actually a relatively delicate machine, and the requirements for the working environment are still relatively strict. Not only does the workshop require as less dust as possible, some may even sensitive to the temperature and need air conditioning to adjust the temperature. Otherwise, there will be chromatic aberrations of different depths due to different frictional heat before, during, and after printing. Not to mention the cold winters and the hot summers. But now Subtextile offers digital printers that equipped with an automatic hot and cold thermostat system, the ink is constant at 25-28 degrees all year round, and the color reproduction degree is 98%.

4.Equip with advanced automatic retractable material system

The retracting and unloading of the printer will also greatly affect the speed of printing heat transfer paper. Some printers have a total card or a reel that can be rolled up with too few consumables, which will greatly reduce the printing speed. Therefore, Subtextile offers sublimation printers with improved receiving and discharging system, like the 1000 air-expansion shaft infrared automatic retracting device, to automation to receive and discharge materials more effictively and intelligently.

Subtextile Co. Ltd.

Export office:

699-18 ,Xuanwu Blvd.,Nanjing City,Jiangsu,China

P.C:213000

Tel:+86 25 85416407 (GLOBAL)

Fax:+86 25 85416407 (GLOBAL)

Cell:+86 17798509616

E-mail:[email protected]

Make an order

- TEL 0086 177 9850 9616

- EMAIL [email protected]

- ADDRESS 7-2 Waisha Village Counclis Bulilding, Baguazhou, Qixia, Nanjing, China

Subtextile © All Rights Reserved.

Choose sublimation paper? Focus on quality over price

Choose sublimation paper? Focus on quality over price

7 Factors To Consider Before Choosing A Digital Textile Printer

7 Factors To Consider Before Choosing A Digital Textile Printer

2024 Apparel Decoration Industry Trends

2024 Apparel Decoration Industry Trends

What are the features of digital textile printing equipment

What are the features of digital textile printing equipment